Manufacturers lose thousands of productive hours every year because issues are detected too late, after quality drops, machines slow down, or energy usage spikes. Most of this waste is preventable. What’s missing isn’t effort. It’s early visibility.

A leading manufacturing client faced this exact challenge. Their data existed, but not in a usable form. Teams were relying on manual checks, delayed reports, and scattered inputs, making it impossible to identify anomalies before they became costly problems.

That’s where Openturf partnered with the manufacturer to implement a smarter detection and optimisation system, one that connected siloed data, flagged issues early, and guided decisions with actionable insights.

What Openturf Built

Openturf deployed an intelligent data layer that:

- Captured real-time data streams from sensors and machines

- Standardised and unified scattered data formats

- Ran anomaly detection on critical parameters

- Triggered insights whenever performance deviated from baseline

- Enabled early alerts for teams to act before damage occurred

Why This Matters

In manufacturing, delays in detection cost more than repairs; they impact throughput, energy consumption, and overall productivity. Openturf’s solution ensured the client could see problems before they became expensive.

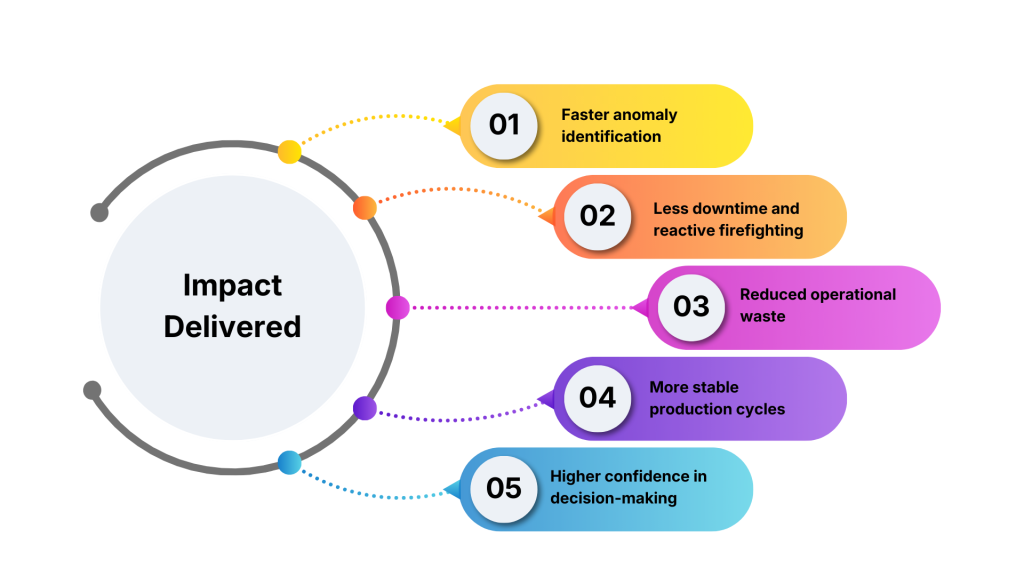

Impact Delivered

The Bigger Picture

This isn’t just analytics. It’s a shift from a reactive environment to a predictive, data-driven manufacturing ecosystem.

Openturf enables manufacturing teams to operate with clarity, speed, and control, exactly what modern factories need to stay competitive.

Dive into the full case study to see how the entire solution was built: https://www.openturf.in/detect-early-optimize-fast-smarter-manufacturing-with-data/